After a short mental-health break, we’re back! Let’s look at some tech! But, first, a quick request - if you like this newsletter, please share it! Through these posts, as you can tell, I’m not just talking about my own experience (which I am, of course) but trying to educate on the process of starting up complex value-added business. If you know someone that would find that kind of information useful, please share these posts and podcast. OK, on to the good stuff …

Largely we can divide meat tech into two categories: plant-based and cellular, though there are variants of each.

Investor and consumer interest in alternative meats is (as we pointed out in Issue #12) at least partially related to the climate change problems of the Big Meat. Take, for example, Branch Investment Group’s investment in Madison-based Cultured Decadence: “Why did Branch Venture Group Invest in Cultured Decadence? … Global warming and increasingly acidic oceans negatively affect wild catch of all seafood, while fossil-fuel intensive harvest methods have an outsized impact on the environment.” Studies show that “lab-grown meat could have the potential to contribute 92% fewer global warming gases and use 95% less land and 78% less water than conventional beef.”1 But there are a variety of reasons that consumers are looking at alternative meats - from general trends of consumers demanding more vegetables and healthier food to addressing systemic issues such as centralization in the processing tier making large-scale meat processing a public health crisis.2

Europe’s largest meat producer, Danish Crown, admits that live-animal meat is likely to become a premium product.

“Beef isn't going to be super climate friendly. It's going to be a bit like champagne, a luxury product. We still want production, but it will be the production of beef and veal from dairy cattle, calves and beef cattle, which graze in the meadow and create biodiversity. The beef cattle will be a luxury product that we eat when we have to treat ourselves.”3

It is predicted that by 2035 alternative meat products will be price-competitive with live animal meats and by 2040 live-animal meat will only comprise 40% of the total meat/alternative-meat market.4

Plant-Based Meats

Plant-based meats are exactly what they sound like, they are products made out of plants - largely legumes and vegetables - that are designed to look and taste like meat. These are the first wave of Meat Tech and largely what is currently available on store shelves and in restaurants. Beyond Meat’s flagship product contains: “peas, mung beans, fava beans, brown rice, cocoa butter, coconut oil, canola oil, potato starch, methylcellulose (a plant fiber derivative), calcium, iron, salt, potassium chloride, beet juice, and apple extract.”

In 2020, there was $1.4 billion in plant-based meat products sold in the US.5 JBS in Europe, and Tyson, Smithfield, Cargill, and Hormel in the US all have plant-based divisions to their live-animal meat empires.6 Impossible Foods is partnering with restaurants and retailers to bring their foods to fast food; they have deals with Burger King such as the Impossible Whopper and now Impossible Nuggets, Kroger is selling the Impossible Burger in 1,700 grocery stores, and Starbucks is selling Impossible Sausage Breakfast Sandwiches.

There are two variants in the “Plant-Based Meat” category. Yeast-based products are similar, but use yeasts instead of legumes and vegetables. These yeasts can be grown in a lab, so do not require any farming whatsoever. Moreover, unlike more “conventional” plant-based meat alternatives, these yeast-based meat alternatives do not use soybeans, which in addition to being a common allergen has questionable farming practices globally.7 Though, not surprisingly, if you’ve ever eaten yeast-based products you know that flavor and texture need a little work.

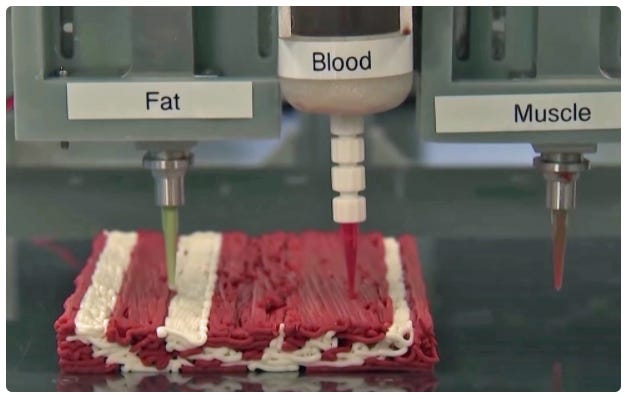

The second variant is “3-D” printed plant-based meats that rather than use Beyond Meat’s “put it all in a ball and smash it like a burger” approach, take the constituent parts and layer them on top of each other. The ingredients in these 3-D printed plant-based products are almost identical to those in more standard plant-based alternatives. For example, “The main ingredients [in Redefine Meat’s Alt-Steak product] are soy and pea proteins, coconut fat and sunflower oil, natural colors including beetroot, water and natural flavors. … [M]ainly so there are no impediments in getting to market, he said. New ingredients take time to be cleared by regulators.”8

One company, SavorEat, sells a 3-D printer for restaurants (ahem: “Robot Chef”). With SavorEat’s printer patrons can customize their plant-based burger such as fat content, taste, and texture right from their table and have it ready in about five minutes. SavorEat will be available in the US in 2022.

Cellular Meats

Finally, are the cellular meats. Cellular meats are meat, or at least I should say, they are muscles and fiber grown from the cells of live animals. These are also grown in a lab and are the bleeding edge (ha!) of current live animal substitutes.

Cultured meat is a form of cellular agriculture where meat is produced by in vitro cell culture of animal cells, instead of through the raising of live animals.9

Just in 2020, investors put more than $1 BILLION behind cultured meat companies.10 But one of the major challenges behind cellular meats is that they need FDA and USDA approval before they can be consumed here in the US.11 This is because food products and production facilities are governed by the FDA, but meat inspection is governed by the USDA. Since these products are, in fact, meat they need approval from both FDA and USDA. By as early as 2040, cultured meats are predicted to, ultimately, be the winner of the new meat technologies and have about 35% of total market share of all meat-like foods about on-par with the predicted market share live animal meat.

How does cellular/cultivated meat work? It’s surprisingly straightforward. The Good Food Institute’s education on cultivated meat is an outstanding resource (and the source for what follows).

Get a stem cell from your animal of choice. From that 1 stem cell, grow about 20,000 cells. Add a little fat, mush it all together, and form it into patty. Grill that bad boy up.

Currently available cell lines are limited, so work is being done by industry and the FDA/USDA to ensure approval and use of a wider variety of cell lines. Another challenge is scaling the cell growth process. The most tested cellular growth processes (used since the 1950’s) use “serum” (i.e., blood plasma) as part of the growth medium along with glucose, salts, and vitamins. Using serum isn’t ideal because drawing plasma is not without consequence to the animal and using enough serum for commercial purposes has ethical challenges. In the short term, the serum is removed before the product is served; in the longer term, industry is developing growth mediums that do not rely on blood plasma.

Once the cell line and growth media have been identified, they are put together in a bio-reactor to start the growth process. One of the bigger challenges with cultivated meat is that current bioreactor designs are not designed for the needs of cultivated meat. For example, many bioreactors can’t operate continuously and need to be shut down regularly, making commercial scale production a challenge.

Finally, if the cultivated meat product will be structured (e.g., a steak) instead of unstructured (e.g., hamburger), then the cells are grown on a scaffold.

“The selection of a scaffold and its properties will be highly dependent on the final product, with the scaffold having an increasingly important role in more structured products. Scaffolds may be intentionally designed to be biodegradable such that they are replaced … by the time a product is harvested. Alternatively, scaffolds can make up a significant portion of the final product, creating a hybrid product. Scaffold materials that end up in a final product must meet requirements for how that product may be cooked and prepared, as well as how the material influences the product’s safety, digestibility, taste, and nutrition.”

Cultivated meat is definitely a few years from being commercially viable. As you may gather, the technical challenges are significant. The challenges are primarily in scaling technology that is known to work. As cell lines, serums, bioreactors, and scaffolds become more commercially scalable it is anticipated that cultivated meat will be the principal source of meat for most Americans.

These technologies will be the competitive environment for live-animal meat. I agree with the statement quoted above that live-animal meat will be a premium product. I also think that sheep, unlike pigs, can improve pasture and grasslands to increase carbon capture and help slow or even reverse climate change. The meat derived from sheep that are improving the land will be a premium product, not the every day food that we consume.

See LA Times article referenced below.

See CB Insights Article linked below. “Meatpacking plants were found to be coronavirus hotspots — nearly 54,000 meatpacking workers have tested positive for Covid-19 and at least 270 have died have died, according to the Food and Environment Reporting Network. Some outbreaks, such as that of a Los Angeles pork production facility owned and operated by Smithfield Foods, have persisted for over a year, with reports of repeated health and safety violations contributing to an ongoing cycle of infection and disruption.”

https://www.berlingske.dk/business/slagteriboss-melder-klart-ud-oksekoed-bliver-et-luksusprodukt-paa-niveau. I should note that this article and the company’s CEO posits that pig can be a good environmentally friendly live-animal meat; personally, I’m hitching my wagon to sheep.